MUNIFLO™ ROTARY LOBE PUMPS

Manufactured since 1985

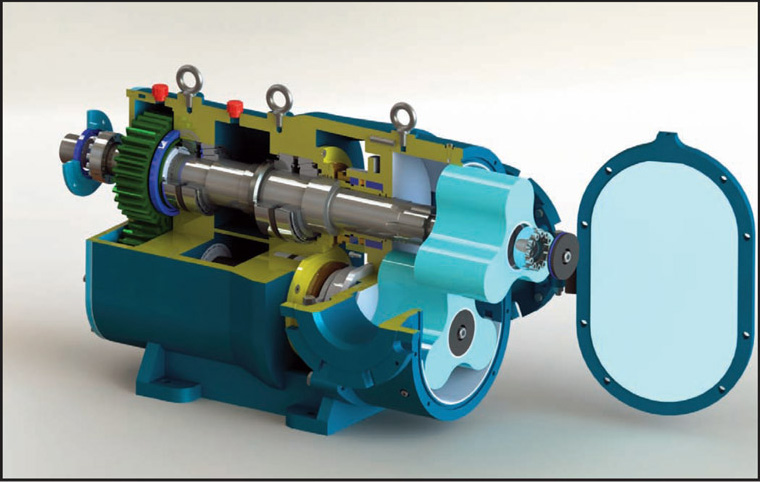

The newly designed Muniflo pump is engineered

to handle all the municipal wastewater product

applications normally associated with ordinary

progressive cavity or other positive

displacement pumps.

Reasons for the superior performance of Muniflo pumps:

- Can run dry for long periods without damage.

- High efficiency over a wide speed range.

- Delicate handling of shear-sensitive products.

- Minimal turbulence and aeration.

- Self priming.

- Handles entrained gases.

- Longer life than progressive cavity pumps.

- Easier maintenance than vale-type plunger pumps or progressive cavity pumps.

- Low internal velocity.

- Rugged abrasian-resistant construction with gear housing of high grade ast iron.

Unique, contoured rotors produce utmost efficiency for pumping both thin and high viscosity products. The round lobes have no sharp cutting edges, so delicate handling of products with discrete particles in suspension can be accomplished with minimal shear damage. Gentle handling is also aided by the gentle, rolling action of the rotors, which produces an exceptionally smooth, even discharge with minimal agitation, pulsation, or aeration.

Controlled tolerance and precision timing insure that neither rotor-to-rotor nor rotor-to-pump-body contact occurs, thus the pump can run dry for long periods of time without damage. This also assures minimal wear.

The Muniflo pump's front cover is easily opened for rapid inspection or cleaning without the need to disconnect the suction or discharge pipelines. The pumping chamber is separated from the gear housing, which permits visual leak detection and reduced heat transmission. This also eliminates any possibility of oil contamination of product or product contamination of oil.

The Muniflo pump also offers these mechanical advantages:

- Wear plates, Radial, Front and Rear

- External timing adjustment.

- Mechanical seal or packed stuffing box option with axially split stuffing box & split gland follower.

- Bearing isolator gear case sealing.

- Straight or Helical rotors available in Ductile Iron, Stainless Steel, Urethane and Buna.

- Hinged front cover with reversable wear plate.

- Separation gap isolating the gear chamber from the rotor case.

- Seepage containment well.

Specifications:

Capacities:........

Pressure:...........

Suction lifts:.......

RPD-5.25,RPD-5.5

RPD-5.75,RPD-6,RPD-8

40 GPM to 900 GPM

To 150 psi

Up to 12 ft.

Muniflo pump operation

The product enteres the suction port and is gently drawn into the pockets formed between the rotors and the rotor case. Lobes on each rotor push the product 180° around the interior of the contoured rotor case and out through the discharge port. Each rotor, equipped with 3 lobes, moves in opposite directions to the other to provide a smooth, uniform flow of material.

APPLICATIONS

- Primary & Secondary Sludge

- Activated Sludge

- Digested Sludge

- Thickening Sludge

- Dewatering Sludge

- Scum

- Waste Sludge

- Tars

- Brewery Waste

- Oil/Water Waste

- Marine Bilge Water

- Waste Oil Sludge

- Lube Oil Sludge

- Gelatin Solutions

- Biodiesel

- Lime Sludge

Pulp and Paper

- Coating Kitchen

- Latex

- Soap Scum

- Clay Slurry

- Bio Solids Sludge

- DAF Sludge

- Thick Juices

- Sugar Syrup

- Waste Sludge